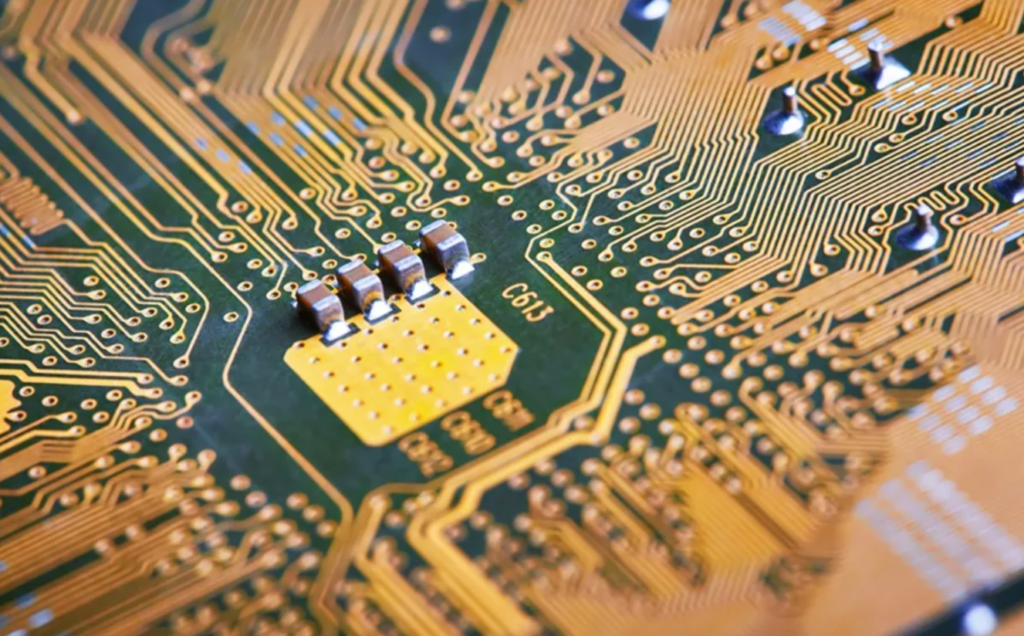

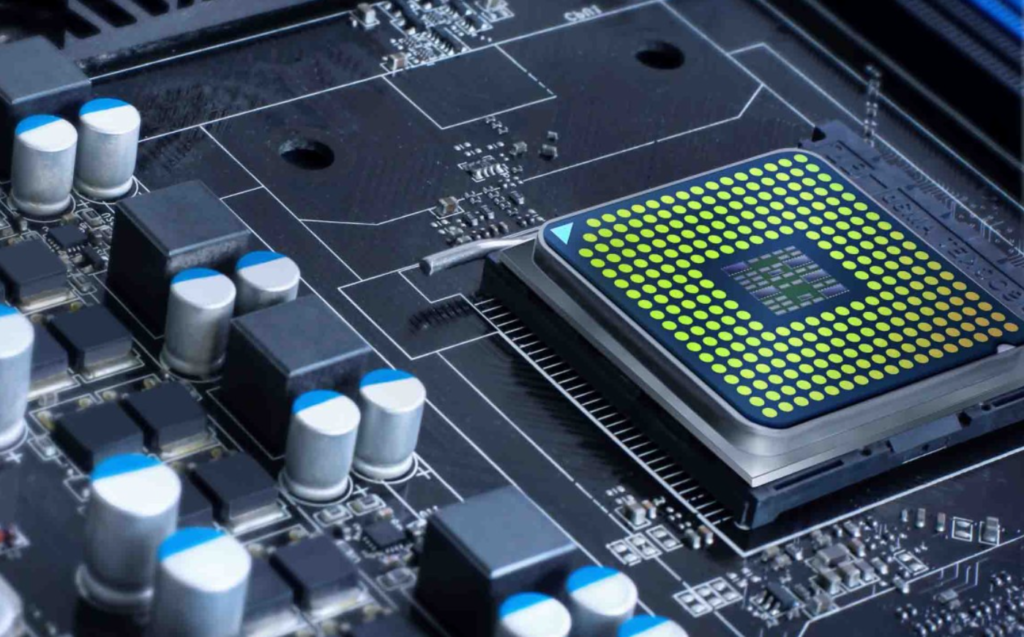

Circuit board design is the foundation of modern electronics, enabling the development of devices like smartphones, computers, and medical equipment. A circuit board, often referred to as a PCB (Printed Circuit Board), serves as the backbone for electronic components, ensuring they function cohesively. Designing circuit boards is a meticulous process involving multiple layers of planning, prototyping, and testing. From future-proofing to manufacturing, circuit board design plays a pivotal role in shaping the performance and longevity of electronic products.

Quick Bio of Circuit Board Design Overview

| Key Term | Description |

|---|---|

| Purpose | Connect and support electronic components |

| Types | Single-layer, Multi-layer, Flexible PCBs |

| Applications | Consumer electronics, Automotive, Medical |

| Design Software | Altium, Eagle, KiCad, OrCAD |

| Challenges | Component obsolescence, thermal management |

| Future Trends | AI-driven design, IoT integration, HDI PCBs |

| Manufacturing Process | Prototyping, Etching, Soldering |

| Importance | Enables functionality and reliability |

| Standards | IPC, RoHS compliance, ISO certifications |

| Core Principles | Flexibility, Modularity, Obsolescence Management |

The Importance of Future-Proofing in Custom Board Design

Future-proofing in circuit board design ensures that a board remains functional and relevant over time, despite rapid technological advancements. This process minimizes the risk of obsolescence, making products more sustainable and cost-efficient.

As industries like IoT and AI continue to grow, circuit boards must be adaptable to new technologies while maintaining compatibility with existing systems. Future-proofing also benefits manufacturers by reducing redesign costs and enabling scalability in product development.

Key Strategies for Future-Proofing Circuit Board Design

To create long-lasting and reliable designs, engineers employ several future-proofing strategies, such as:

- Emphasizing flexibility and modularity for adaptability.

- Using long-life components that minimize the risk of obsolescence.

- Establishing a robust supply chain for consistent component availability.

- Implementing design for manufacturing (DFM) principles for scalability.

These strategies help ensure that circuit boards remain relevant and functional even as technologies evolve.

Design for Flexibility and Modularity

Flexibility and modularity are essential for adapting circuit boards to future requirements. A modular design allows engineers to replace or upgrade individual components without redesigning the entire board.

For instance, in IoT applications, modular boards make it easier to integrate additional sensors or communication interfaces. Flexible designs, on the other hand, are crucial in applications like wearable electronics, where circuit boards must conform to unique shapes and movements.

Benefits of a Flexible and Modular Design

- Scalability: Modular designs simplify system expansion by enabling the addition of new components.

- Cost-Effectiveness: Reusable modular components reduce redesign costs.

- Versatility: Boards with flexible layouts can adapt to different use cases or environments.

By incorporating flexibility, circuit boards remain relevant for longer and support evolving applications.

Techniques for Achieving Flexibility and Modularity

Achieving flexibility and modularity in design requires innovative techniques, such as:

- Using pluggable modules for critical components.

- Designing generic component footprints to accommodate upgrades.

- Incorporating flexible interconnects that support layout adjustments.

These approaches allow for greater adaptability, ensuring that circuit boards meet future needs without frequent redesigns.

Select Long-Life Components

One of the most effective ways to future-proof circuit board design is by selecting components with long production lifespans. Such components minimize the risks associated with obsolescence and ensure product reliability.

For example, industrial-grade microcontrollers and capacitors often have longer lifespans compared to consumer-grade alternatives. These components are ideal for applications in automotive, aerospace, and medical devices, where durability is critical.

Factors to Consider When Selecting Long-Life Components

To choose long-life components, engineers evaluate the following factors:

- Lifecycle Data: Understanding the expected production lifespan of a component.

- Compatibility: Ensuring the component aligns with current and future design requirements.

- Supplier Reliability: Partnering with reputable manufacturers to ensure consistent supply.

Examples of Long-Life Components

Some examples of components that are commonly used in long-lasting circuit board designs include:

- Industrial-Grade Microcontrollers: Designed for extended availability and performance.

- Ceramic Capacitors: Known for their durability and resistance to environmental stress.

- Shielded Inductors: Frequently used in applications requiring high reliability.

These components enhance the longevity and reliability of circuit boards.

Establish a Robust Supply Chain

A strong supply chain is critical for ensuring the consistent availability of components throughout a product’s lifecycle. Disruptions in the supply chain can lead to delays or product redesigns, significantly increasing costs.

By working with multiple suppliers and monitoring component availability, manufacturers can reduce risks and maintain seamless production processes.

Strategies for Building a Robust Supply Chain

To build a reliable supply chain, companies should:

- Partner with multiple vendors to avoid dependency on a single supplier.

- Track end-of-life notifications for critical components to plan ahead.

- Establish long-term agreements with manufacturers for stable supply.

Benefits of a Strong Supply Chain in Combating Obsolescence

A well-maintained supply chain reduces the likelihood of:

- Component shortages, which can delay production.

- Redesign costs, as alternate components may not fit the existing design.

- Unplanned downtime, ensuring products reach the market on time.

Implement Design for Manufacturing (DFM) Principles

DFM is the practice of optimizing circuit board designs for efficient and error-free manufacturing. It ensures that the board is not only functional but also cost-effective to produce.

For example, simplifying the board layout and ensuring proper spacing between components minimizes production errors and speeds up the manufacturing process.

Key DFM Principles for Future-Proofing

Some essential DFM principles include:

- Simplifying PCB layouts to ensure easy assembly and repair.

- Adhering to industry standards for better compatibility.

- Using widely available materials to ensure long-term manufacturability.

Benefits of Implementing DFM in Custom Board Design

By adopting DFM principles, manufacturers benefit from:

- Lower production costs due to optimized processes.

- Faster time-to-market with error-free production runs.

- Enhanced adaptability for future design modifications.

Embrace Standardization and Common Interfaces

Standardization is an important aspect of circuit board design, as it ensures compatibility with other devices and systems. Using common interfaces like USB-C, HDMI, and PCIe makes boards more versatile and easier to integrate into various applications.

Benefits of Standardization and Common Interfaces

- Simplified Repairs: Standardized components are easier to replace.

- Enhanced Compatibility: Broader compatibility across devices and industries.

- Longevity: Compliance with industry standards ensures long-term usability.

Plan for Obsolescence Management

Obsolescence is inevitable in circuit board design, but proactive management can mitigate its effects. Planning for obsolescence involves tracking the lifecycle of components and identifying alternatives well in advance.

Elements of an Effective Obsolescence Management Plan

A robust obsolescence management plan includes:

- Keeping a detailed inventory of component lifecycles.

- Establishing relationships with aftermarket suppliers.

- Using design tools that flag obsolete parts during the design phase.

The Role of Electronic Product Development in Future-Proofing

Future-focused product development ensures that circuit boards are designed to meet both current and emerging industry trends. This involves using cutting-edge technologies like AI-driven simulations and predictive modeling to create adaptable designs.

Conclusion

Circuit board design is at the heart of modern technology, enabling innovation across industries like healthcare, automotive, and consumer electronics. By incorporating strategies like future-proofing, selecting long-life components, and adhering to DFM principles, engineers can create reliable, scalable, and sustainable circuit boards.

As the industry evolves, embracing trends like AI integration and IoT connectivity will further enhance the potential of circuit board design. Whether you’re a manufacturer or a designer, investing in future-proof strategies ensures long-term success and innovation in a competitive market.

FAQs

What is circuit board design?

Circuit board design involves creating the layout and connections for electronic components to work cohesively within a device.

Why is future-proofing important in circuit board design?

Future-proofing ensures that circuit boards remain functional and adaptable, reducing obsolescence risks and saving costs on redesigns.

What are long-life components?

Long-life components are parts designed for extended availability, ensuring the reliability and longevity of circuit boards.

What are some common standards in circuit board design?

Standards like USB-C, HDMI, and Ethernet ensure compatibility and extend the lifespan of circuit boards.

How does DFM benefit circuit board manufacturing?

DFM minimizes production errors, reduces costs, and ensures scalable designs for efficient manufacturing.

Visit For More Information:- Hollywood Magazine

Leave a Reply